bag filter sizing calculation

Liquid Filter Bag Sizing Guide

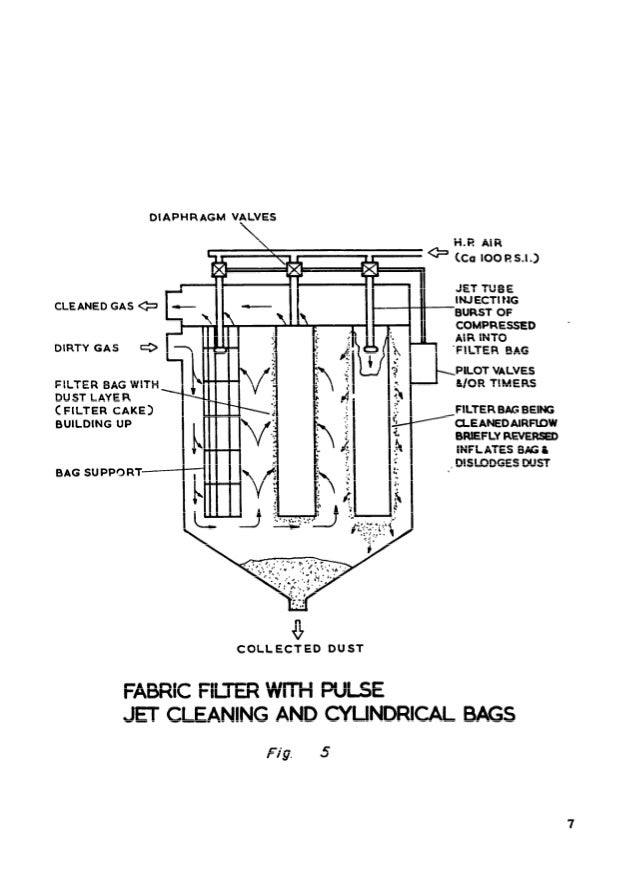

Liquid Filter Bag Sizing GuideRead more about Sly Inc. through the blog post below: Dust Collector Fold: What size do you need? A dust collection system is essential for any manufacturing process that creates harmful discomfort or contaminants in a confined environment. A powder collector filters air particles from factory, collects dust for disposal and returns clean air to the environment. Alternatively, dust collector can be an integral part of a dust processing system. If the a is of inappropriate size, the matter of escaped particles can be harmful to the employee's breathing and general health. The dust can obstruct or reduce the efficiency of the factory equipment, and increase maintenance costs. In a process system, an improper-sized dust collector may restrict or limit production rates. When choosing the correct size of the powder collector, it will work at maximum efficiency, improving safety, compliance and overall productivity. Multiple factors need to be considered when selecting a dust collector system. With an understanding of these basic parameters, you will see why your calculation and application to your bag will benefit your process. Determine the correct sized powder collector for your factory provides budget-based investment performance. The three primary calculations to determine the size of the powder collector you need are the air volume, the relationship between air and body and the interstitial speed. Air volume The air volume is the amount of air that will pass through the dust collector for cleaning. This is measured in cubic feet per minute (CFM). CFM determination in HoodsC F M = fpm x area In this calculation, fpm are feet per minute of air speed. Depending on the characteristics of the powder, the correct CFM value should be approximately 100–200 feet per minute of air speed multiplied by the cross-section of the hood in square feet. The precise measurement of the air volume that crosses the baghouse is vital for proper ventilation. Inadequate ventilation can block equipment, create an unsafe working environment and increase problematic environmental emissions. If there are any questions about the correct CFM for your process, contact your professional bag provider. Heat air ratioIn the bag, the cloth filter bags are the work horses in the dust collection process. These filter bags (also known as filter socks or filter tubes) are suspended from a tube sheet in the baghouse. The dirty air passes over or through them (depending on the used bag technology), and the dust adheres to the means of filtration. In a pulse injection collector, bags are automatically cleaned without leakage interruption (line cleaning). The relationship between air and body is the volume of air passing through a square foot of the filtering media. An air-to-body ratio can extend the life of the filter, while a higher-body-to-air ratio could reduce the life of the filter. This relationship should be adapted to specific application conditions for maximum efficiency and filtering life. To calculate the relationship between air and body, divide the volume of air flowing through the input ducts of the powder collector by the total area of the cloth. The importance of the correct relationship between air and body becomes even more evident in interstitial speed. Intersticial Speed Interstitial speed refers to the ascending air movement in the space between filter bags in the dust collector. If the interstitial speed is too high, the powder pressed out of the bag will be re-trained back into the bag instead of falling into the hopper for disposal. This can cause problems, including: To design a powder collector for proper interstitial speed, Benefits of a correct sized bagThe dust collection is an essential and often regulated component of any process that produces dust. Working with a professional supplier of good reputation or OEM will ensure that your air quality goals and dust recovery requirements are met. Its productivity advantages and cost savings with a suitable sized and calibrated baghouse include: A bag that is too large for installation is a waste of resources in terms of cost, footprint and energy. Go too small with your baghouse, and it may seem that you have saved your initial investment, but inefficiencies in the collection could damage your staff, equipment and output. Sly is happy to work with you to get the right sized baghouse. You can or . We hope to help you. hbspt.cta._relativeUrls=true;hbspt.cta.load(2026920, '0d888cb5-4f0d-4793-a05e-21260a76f204', {}); Tags: Subscribe to our BlogObligatory DOWNLOAD THE SLY GENERAL BROCHURESLY LLC – CORPORATE OFFICE8300 Dow Circle, Suite 600 Strongsville, OH 44136© 2020 SLY LLC All rights reserved.

Maximizing Dust Collection System Efficiency | Compressed Air Best Practices

Designing and Sizing Baghouse Dust Collection Systems

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

Designing and Sizing Baghouse Dust Collection Systems

Bag Filter Design Calculation Xls - DesaignHandbags

Bag Filter Calculation: Sizing Your System for Performance

Bag Filter Design Calculation Xls - DesaignHandbags

Bag Filter Calculation: Sizing Your System for Performance

Bag filters

The pulse of dust collectors

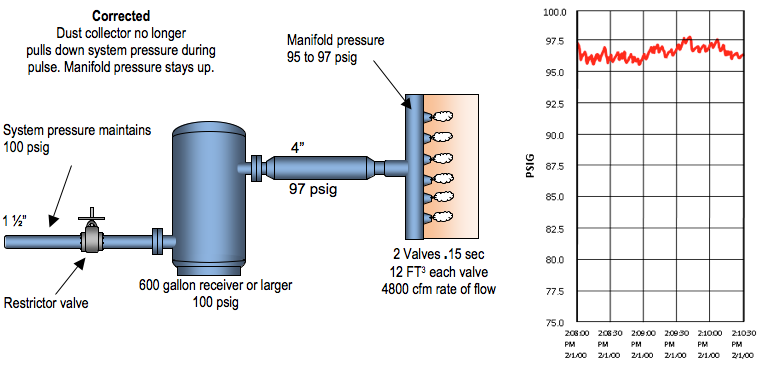

Maximizing Dust Collection System Efficiency | Compressed Air Best Practices

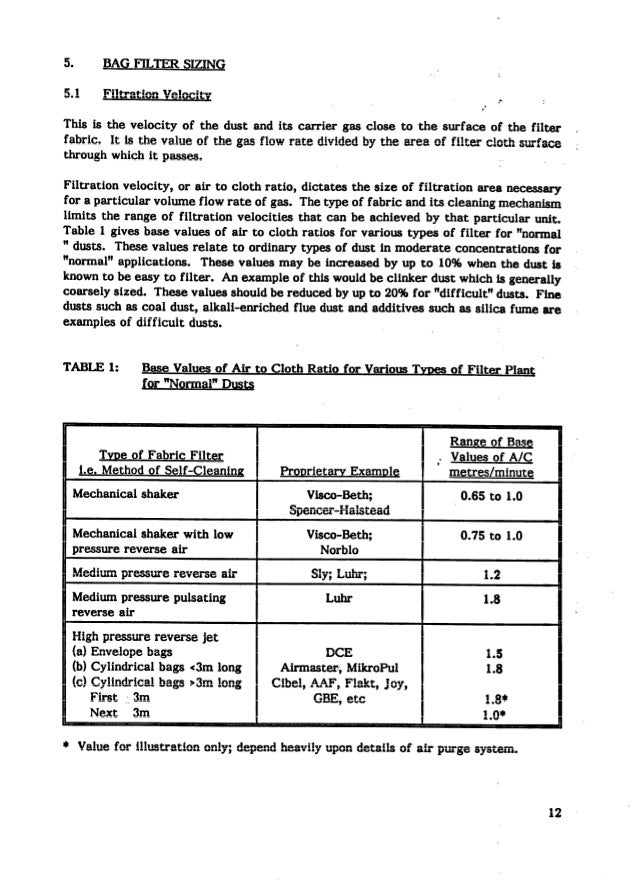

Filtration

Maximizing Dust Collection System Efficiency | Compressed Air Best Practices

Bag Filter Calculation: Sizing Your System for Performance

bag: Pulse Jet Bag Filter Design Calculation Xls

Liquid Filter Bag Sizing Guide

10 Tips to Optimize Dust Collection System Performance | powderbulksolids.com

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

Pulse Jet Solenoid Valve - How They Work | Tameson

Bag filters

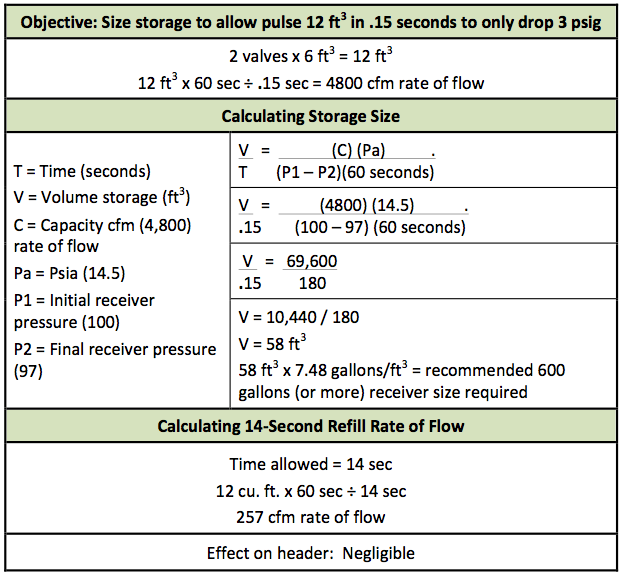

BAG FILTER SYSTEM SIZING

The pulse of dust collectors

BAG FILTER SYSTEM SIZING

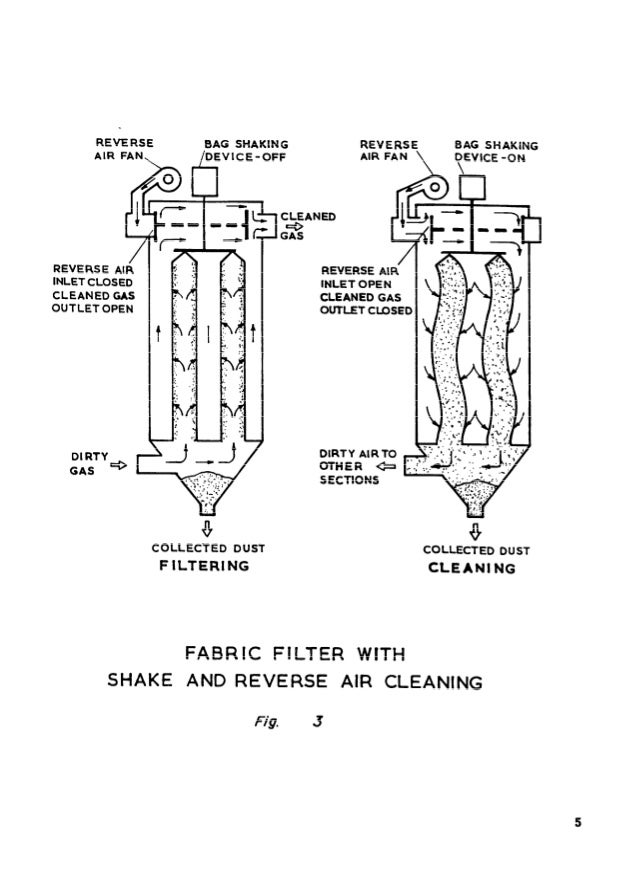

Working, Design Considerations and Maintenance of Bag Type Fabric Filters

Maximizing Dust Collection System Efficiency | Compressed Air Best Practices

Bag Filter Design Calculation Xls - DesaignHandbags

PULSE JET BAG FILTER DESIGN - PULSE JET BAG FILTER DESIGN Flow gas rate Temperture Concentration of the dust in gases Average diameter of the particle | Course Hero

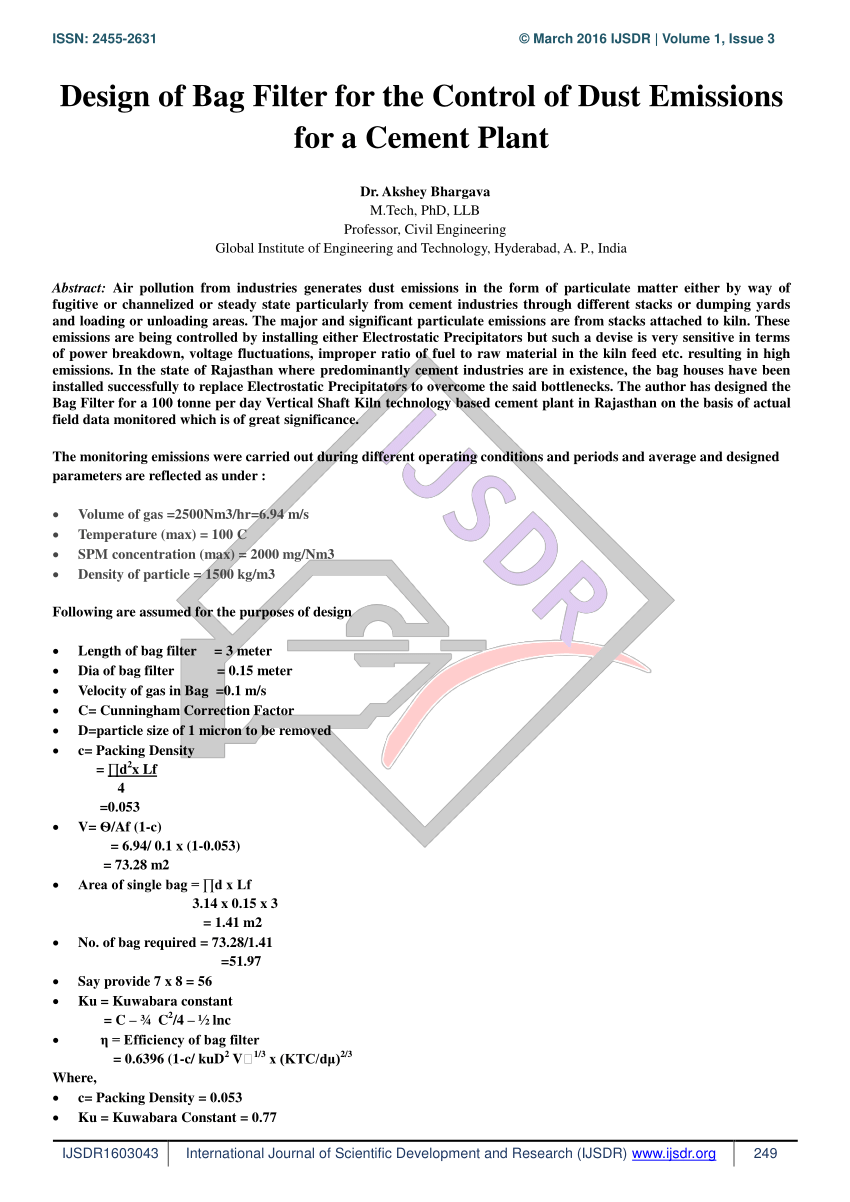

PDF) Design of Bag Filter for the Control of Dust Emissions for a Cement Plant

The pulse of dust collectors

Bag filters

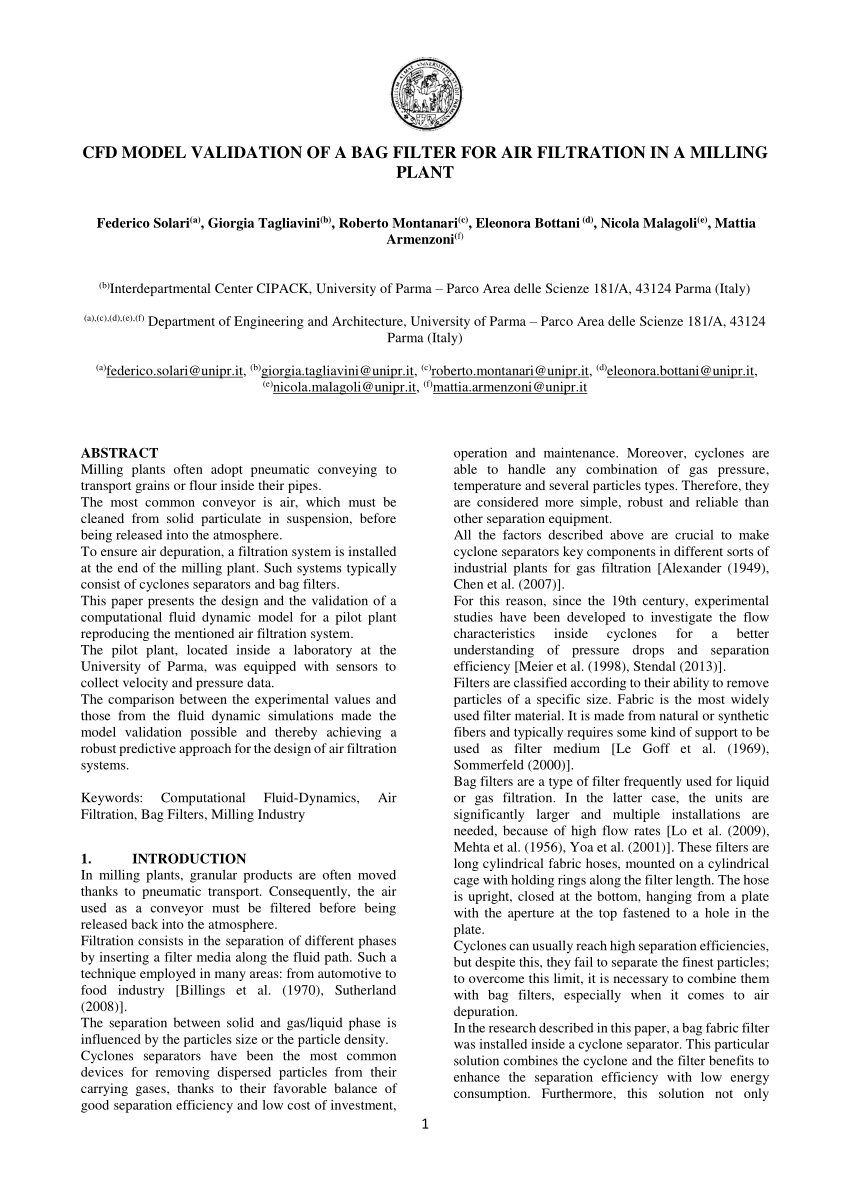

PDF) CFD MODEL VALIDATION OF A BAG FILTER FOR AIR FILTRATION IN A MILLING PLANT

Air Filtration in AHU's - The Engineering Mindset

Working, Design Considerations and Maintenance of Bag Type Fabric Filters

Bag Filter Calculation | Gases | Mechanics

Fabric Filter Baghouses - an overview | ScienceDirect Topics

Industrial Filtration Equipment - Bag & Disc Filters - Sand Media Filters | Thermal Care, Inc.

Pharma Engineering: Filtration Equipment, Types of Filters & Their Selection

Student Manual Chapter 7

Understanding Cooling Tower Filtration Options | 2000-03-01 | Process Cooling

Posting Komentar untuk "bag filter sizing calculation"